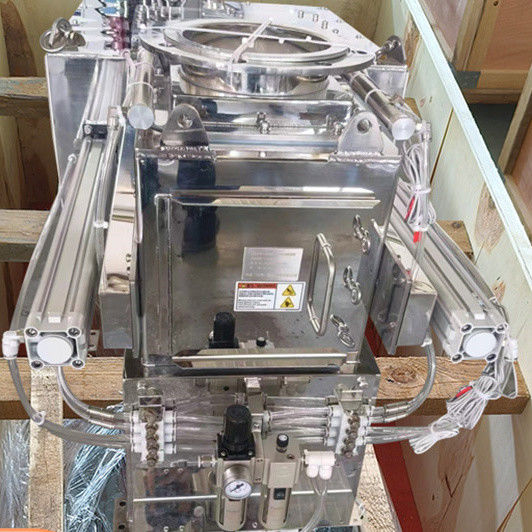

Self-cleaning rotary magnetic separator, a new benchmark for iron removal in the lithium battery industry, features a rotating design to eliminate the risk of clogging

In the rapidly developing lithium battery industry, the performance of iron removal equipment directly affects battery quality and production efficiency. This self-cleaning rotary iron remover has become a new industry benchmark with its innovative rotating structure and efficient iron removal capability. It completely solves the pain point of traditional equipment being prone to clogging, providing stable and reliable iron removal guarantees for lithium battery production.

Core Advantages

- Rotating Design Prevents Clogging: Adopting a 360° rotating magnetic roller combined with a streamlined flow-guiding structure, materials form a spiral movement trajectory when flowing through, avoiding accumulation and 结块 inside the equipment. Even when handling high-viscosity slurries (viscosity ≤ 8000cP), it can maintain smooth flow, fundamentally eliminating clogging risks and reducing downtime for cleaning.

- Efficient Iron Removal Sets a New Benchmark: Equipped with high-density neodymium-iron-boron magnets, the magnetic field strength reaches up to 18,000 Gauss, which can accurately capture iron impurities with a particle size ≥ 0.01mm. The iron removal efficiency is over 99.9%, controlling the iron content in lithium battery materials within 5ppm, far exceeding industry standards, and helping to improve battery cycle life and safety.

- Adapts to Full-Process Production: It can perfectly adapt to iron removal of positive electrode materials (ternary, lithium iron phosphate), negative electrode materials (graphite) in powder form, as well as online iron removal in the slurry mixing process. It can be directly connected to existing production lines without large-scale modifications, and the installation and commissioning cycle only takes 24 hours.

Technical Parameters Table

Frequently Asked Questions

Q1: Will the rotating structure increase equipment energy consumption?

A1: No. The rotating drive uses a high-efficiency and energy-saving motor with a power of only 1.5-3kW. Compared with traditional equipment, while achieving the anti-clogging function, energy consumption is reduced by about 20%, making it more economical for long-term use.

Q2: Can it effectively remove iron from lithium battery raw materials containing fiber impurities?

A2: Yes. The equipment is equipped with a pre-filter screen (100-200 mesh) to first intercept large impurities such as fibers, and then the rotating magnetic roller adsorbs iron particles. With double protection, the iron removal effect is not affected.

Q3: How to judge if the equipment needs maintenance?

A3: The equipment is equipped with an intelligent monitoring system. When the rotation speed is abnormal, the magnetic field strength drops by more than 10%, or the iron chip collection box is full, it will automatically issue an audible and visual alarm to remind for maintenance, and the operation is simple and intuitive.

Q4: Can it adapt to the corrosive environment of lithium battery workshops?

A4: Absolutely. The parts of the equipment in contact with materials are made of 316L stainless steel, and the surface is treated with Teflon coating, which has excellent acid and alkali corrosion resistance and can operate stably for a long time in an environment with pH value 3-11.

Q5: What are the advantages in service life compared with traditional iron removers?

A5: The average service life of traditional equipment is 3-5 years. The rotating parts of this equipment use wear-resistant ceramic bearings, and the magnets are treated with anti-demagnetization. With normal maintenance, the service life can reach 8-10 years, greatly reducing equipment replacement costs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!