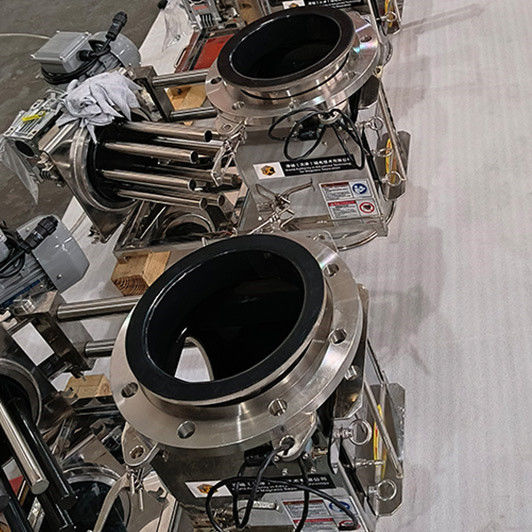

Customized self-cleaning rotary magnetic separator, suitable for complex working conditions in the lithium battery industry, provides powerful iron removal without blind spots

Lithium battery production involves complex working conditions, and different stages from raw material pretreatment to slurry mixing have varying requirements for the adaptability of iron removers. This custom self-cleaning rotary iron remover can be tailor-made according to the specific needs of the lithium battery industry. With its flexible customization options and powerful iron removal capability, it easily handles complex scenarios such as high temperature, high viscosity, and high dust, achieving all-round iron removal without dead angles, thus building a solid defense for battery quality.

Core Highlights

- Customized Design for Working Conditions: It can be customized in terms of magnetic field strength (8000-20000 Gauss), pipeline material (316L stainless steel/titanium alloy), and protection level (IP65/IP67) according to specific links in lithium battery production (such as iron removal after cathode material calcination, iron removal during anode slurry mixing, etc.), so as to adapt to different material properties and environmental requirements.

- Powerful Iron Removal Without Dead Angles: Adopting multiple sets of inclined magnetic rod arrays and a 360° rotating cleaning structure, there is no retention area when materials flow through. Even dead angles prone to material accumulation, such as pipeline corners and valve connections, can be fully covered by the magnetic field, ensuring that iron impurities have nowhere to hide.

- Intelligent Adaptation to Complex Environments: Aiming at high temperature (≤150℃), corrosive gases and other conditions in lithium battery workshops, it is equipped with a high-temperature heat insulation layer and anti-corrosion coating, and is also equipped with a dust protection device, ensuring stable operation of the equipment under complex working conditions with a service life of more than 8 years.

Technical Parameters Table

Frequently Asked Questions

Q1: Can the equipment size be customized according to the production line space?

A1: Yes. It supports customization of equipment shape and installation angle according to workshop layout and pipeline direction. It can be adapted to narrow spaces with a minimum width of only 500mm without affecting the original production line layout.

Q2: Will high-viscosity slurry affect the iron removal effect?

A2: No. For slurries with viscosity >3000cP, a model with a stirring and flow-guiding structure can be customized, which is matched with low-speed rotating magnetic rods to ensure that the slurry is fully in contact with the magnetic field, and the iron removal efficiency is maintained above 99%.

Q3: How long is the customization cycle?

A3: The regular customized models take 7-10 working days, and the models with special materials (such as titanium alloy) or complex structures take 15-20 working days. Expedited services can be provided to meet the needs of urgent production.

Q4: How to match the iron removal needs of different lithium battery materials?

A4: For ternary materials, the 15000-20000 Gauss strong magnetic model can be selected; for lithium iron phosphate, the 12000-15000 Gauss model is suitable; for graphite anodes, the 8000-12000 Gauss model is a good choice. Engineers will recommend the optimal solution according to material characteristics.

Q5: Does it support linkage with the production line control system?

A5: Yes. It can be integrated with a PLC interface and connected with the workshop MES system to upload iron removal data, fault warnings and other information in real time, realizing automatic production monitoring and intelligent scheduling.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!