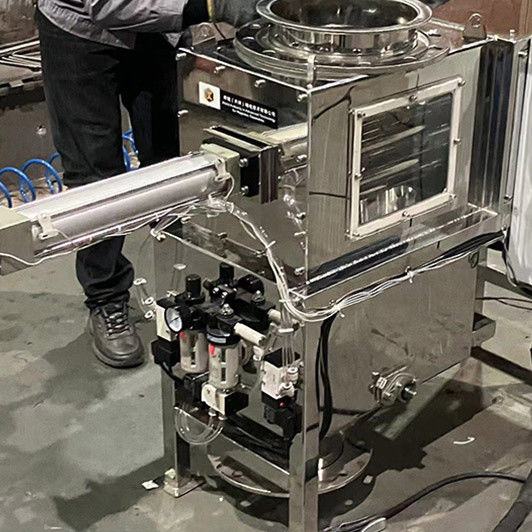

Self-cleaning rotary magnetic separator is essential for lithium battery production, easily keeping the iron content within 10ppm

In lithium battery production, the presence of iron impurities is a critical hazard affecting battery performance and safety. This self-cleaning rotary iron remover is specifically designed for lithium battery production scenarios. With its precise iron removal capability and intelligent self-cleaning function, it has become a core equipment to ensure battery quality, stably controlling the iron content in raw materials within 10ppm and safeguarding efficient production.

Core Advantages

- High-Precision Iron Removal: Adopts a high-gradient strong magnetic design with a magnetic field strength of 12,000-18,000 Gauss, capable of capturing micron-level iron impurities. Through multi-layer magnetic circuit layout, it ensures iron removal precision is stably within 10ppm, meeting the high purity requirements of lithium battery materials.

- Self-Cleaning & Maintenance-Free: The rotating magnetic roller structure is equipped with an automatic iron scraping device, which cleans adsorbed iron chips every 30 minutes without manual shutdown operation, reducing production interruptions and adapting to 24-hour continuous production rhythm.

- Compatible with Full Lithium Battery Production Process: Compatible with cathode materials (ternary, lithium iron phosphate), anode materials (graphite) and slurry mixing links. The pipeline design can be seamlessly integrated into existing production lines, with convenient installation.

Technical Parameters Table

Frequently Asked Questions

Q1: Can it handle high-viscosity lithium battery slurries?

A1: Yes. The equipment adopts a large-diameter pipeline and low-resistance flow channel design, which can adapt to slurries with viscosity ≤5000cP, ensuring smooth passage of materials without blockage and without affecting iron removal efficiency.

Q2: How to verify if the iron removal precision meets the standard?

A2: Before leaving the factory, it is tested with standard iron powder solution to ensure iron removal precision ≤10ppm; users can regularly sample and test with atomic absorption spectrometer, and the data is traceable.

Q3: Will iron chips cause secondary pollution during self-cleaning?

A3: No. The cleaned iron chips are collected through a sealed waste box, which is completely isolated from the material flow channel, preventing the fallen iron chips from re-mixing into the raw materials and ensuring stable iron removal effect.

Q4: Does installation require modification of the existing production line?

A4: No large-scale modification is needed. The equipment adopts flange connection, which can be directly connected to existing pipelines, and supporting reducing joints are provided. The installation time is usually no more than 4 hours, without affecting the production plan.

Q5: Is it suitable for small laboratory production lines?

A5: Yes. There is a mini model (processing capacity 5-10t/h) with a compact size (length × width × height = 800 × 600 × 1200mm), which can meet the iron removal needs of small-batch production in laboratories, with the same precision as the industrial model.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!