All iron miscellaneous things are eliminated! Dry powder iron removal equipment magnetic separator Iron removal expert in non-ferrous metal smelter.

Use: It is used to remove magnetic impurities from dry powder materials, mainly including new energy battery materials (ternary materials, ternary precursors, lithium iron phosphate, ferric phosphate, lithium carbonate, lithium hydroxide, negative electrode graphite, silicon - carbon negative electrode, sodium - ion battery materials, etc.), food, quartz materials, etc.

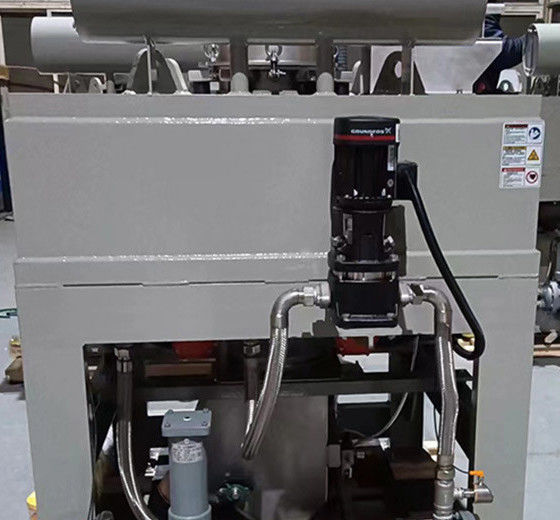

Working principle: When the electromagnetic coil is energized, it forms a magnetic circuit with the carbon steel box. The magnetic - conducting medium in the hollow cavity gathers the magnetic field to form a high - intensity and high - gradient separation. When the material passes through the magnetic - gathering medium, the material falls from the outlet, and the magnetic substances are adsorbed onto the medium. A three - way diverter valve is installed at the bottom of the material channel. Through the PLC, the flap is automatically controlled to separate the magnetic substances from the material. The vibration devices installed at both ends of the discharge pipe adopt high - frequency vibration to increase the passing capacity of the material. The transformer oil circulates for cooling to ensure the safety of the coil. It adopts the HMI human - machine interaction interface for operation and PLC full - automatic control, which realizes automatic iron removal, automatic slag discharge, automatic alarm, and can achieve unmanned automatic operation and status monitoring.

Product Advantages

High - Efficiency Iron Removal: Thanks to their unique magnetic system design and strong magnetic field, dry powder magnetic separators can quickly and effectively remove magnetic impurities from materials. The iron - removal rate is as high as over 99%, significantly improving product purity and meeting high - quality production requirements.

Strong Adaptability: Whether it is fine - grained powders or materials with different magnetic strengths, dry powder magnetic separators can achieve accurate magnetic separation by adjusting parameters or selecting suitable models. They are widely applicable to various industries and production scenarios.

Cost Reduction: On the one hand, the equipment operates stably with a low failure rate, reducing economic losses caused by equipment maintenance and downtime. On the other hand, the high - efficiency magnetic separation performance reduces material waste and improves resource utilization, reducing production costs for enterprises.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!