The permanent magnet roller magnetic separator purification equipment for screening lithium battery materials enables efficient separation.

Permanent magnet roller iron separator Using super permanent magnet magnet as magnetic source, mainly for continuous purification of weak magnetic impurities, when the material through the feeder evenly into the division, the magnetic material with the conveyor tape, the magnetic material along the tangent direction of the inertia, so that the magnetic and the magnetic material, separated, and the whole process of automatic separation. Single or multi-layer design, the magnetic roll width is 500mm, 1000mm, 1500mm, and the material processing capacity can reach 30m ³ / hour or 20T / hour. Low power consumption saves electricity; the magnetic field can reach 14000GS, good iron removal effect. Application: lithium electric materials, diamond jade, silicon nitride, garnet, refractory materials, feldspar, quartz

Selection Guide

Selection Based on Impurity Removal Rate Requirements and Site Environment:For places with high iron removal requirements,such as coal transportation ports and large thermal power plants,choose permanent magnetic separators with high magnetic field strength and good iron removal effects.In harsh environments like dusty and humid conditions,select equipment with good sealing performance and strong environmental adaptability.

Consideration of Installation Location:When installed at the head of the belt conveyor,the materials are in a loose state when leaving the belt,which is conducive to iron removal.When installed in the middle of the belt conveyor,non-magnetic flat idlers can be used to improve the iron removal effect.Special designs are required for special site environments.

Configuration for Multi-Stage Iron Removal:When multi-stage iron removal is adopted,the iron removal capacity of the subsequent stage should be stronger than that of the previous stage to ensure the iron removal effect.

Parameters

|

ID(mm)

|

Outer Dimension(mm)

|

Layer

|

Bar quantity

|

Height(mm)

|

Peak Value

|

|

DN150(φ159)

|

220X200

|

3

|

7(2+3+2)

|

370

|

16000 GS

|

|

DN200(φ219)

|

270X260

|

3

|

10(3+4+3)

|

370

|

15000 GS

|

|

DN250(φ273)

|

330X300

|

3

|

13(4+5+4)

|

370

|

|

|

4

|

18(5+4+5+4)

|

440

|

14000 GS

|

|

6

|

27(5+4+5+4+5+4)

|

580

|

|

|

DN300(325)

|

390X370

|

3

|

16(5+6+5)

|

430

|

13000 GS

|

|

4

|

22(5+6+5+6)

|

520

|

|

|

6

|

33(5+6+5+6+5+6)

|

610

|

12000 GS

|

Technical Advantages

Energy-Efficient:Utilizing high-performance permanent magnetic materials like neodymium iron boron as the magnetic source,it does not require excitation coils and rectifier control devices,eliminating excitation current.This results in energy savings,and without temperature rise issues,the magnetic field strength remains constant,regardless of"cold"or"hot"states.

Stable Performance:The selected permanent magnetic materials have extremely low demagnetization characteristics.Under normal use conditions for 10 years,the attenuation rate of magnetic properties does not exceed 3%,ensuring long-term stable operation of the equipment.The equipment has a reasonable structural design,such as the use of sealed bearing housings and drum-shaped rollers,which reduces failure points and improves reliability,allowing it to adapt to harsh environments like high or low temperatures,humidity,and dust.

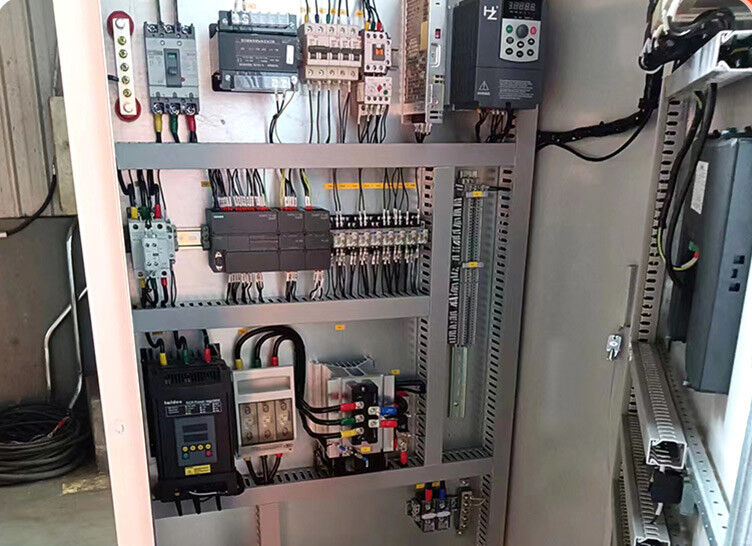

Flexible Control:The control part can be interlocked with the belt conveyor,enabling two control methods:local manual control and centralized control.This allows operators to flexibly adjust according to actual production situations.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!