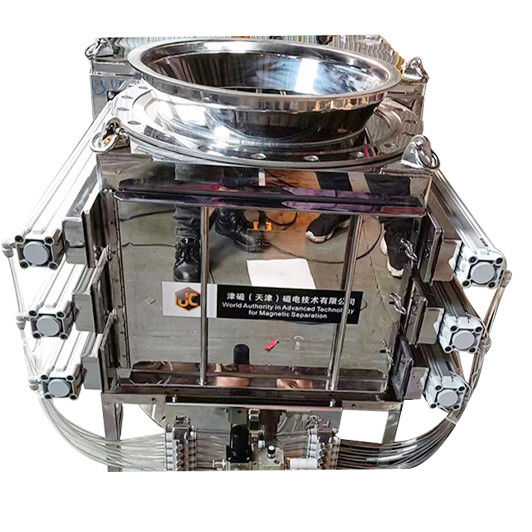

Dry powder type permanent magnetic iron remover, applicable to the food industry, is intelligently controlled by PLC, which can reduce energy consumption.

Working Principle

By leveraging the high-intensity magnetic field region formed by permanent magnets,when materials containing magnetic impurities pass through the magnetic field area of the separator,the magnetic impurities are attracted to the surface or interior of the separator under the action of the magnetic force,thus separating from the materials and achieving the purpose of iron removal.

Applications

It is used to remove ferromagnetic impurities from dry powdery,flaky,granular,and other materials.It is commonly applied in battery anode and cathode materials such as lithium carbonate,lithium hydroxide,lithium iron phosphate,ternary precursors,and ternary materials,as well as in ceramics,chemical engineering,plastics,mining,food,and other industries.

Features

No Electric Power Needed:The permanent magnetic separator operates relying on the magnetic field of permanent magnets,eliminating the need for external power supply.This saves energy,reduces operating costs,and ensures that the iron removal effect will not be affected by power outages.

High Magnetic Field Strength:By using high-performance permanent magnetic materials,it can generate a powerful magnetic field,effectively adsorbing even tiny magnetic impurities and achieving high iron removal efficiency.

Simple Structure:The equipment has a relatively simple structure,facilitating maintenance.With a long service life,it reduces equipment maintenance costs and downtime.

Strong Adaptability:Different types and specifications of permanent magnetic separators can be selected according to various material characteristics and iron removal requirements,enabling it to adapt to harsh working environments.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!