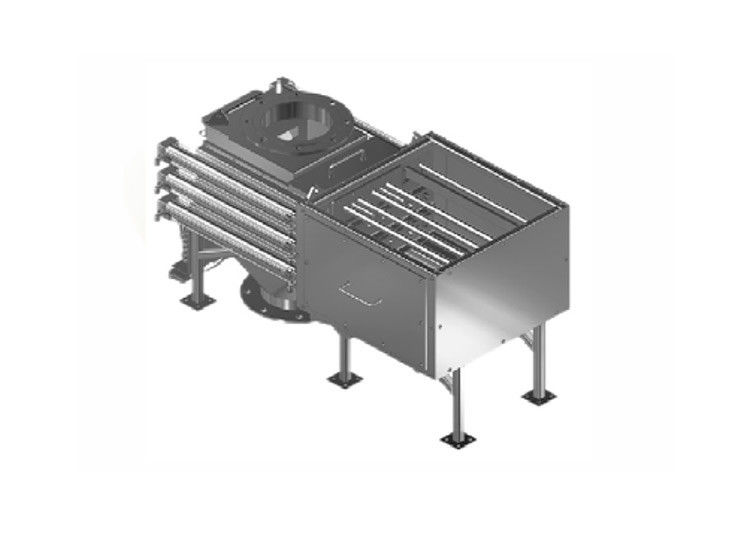

Pneumatic Self-clean Drawer type Magnetic Separator - Super Strong Permanent Magnet, Multi - Layer Design for Enhanced Iron Removal in Powdery Substances

Structural Composition

Magnetic System:It is the core component of the permanent magnetic separator,composed of high-performance permanent magnetic materials such as neodymium iron boron,which can generate a strong and stable magnetic field.

Shell:Generally made of stainless steel or carbon steel,it protects the magnetic system and supports the structure.It also has excellent wear resistance and corrosion resistance.

Drive Device:For some rotating permanent magnetic separators,such as belt-type permanent magnetic separators,the drive device is used to drive components like conveyor belts or magnetic drums to rotate,enabling materials to pass through the magnetic field area evenly.

Applications

It is used to remove ferromagnetic impurities from dry powdery,flaky,granular,and other materials.It is commonly applied in battery anode and cathode materials such as lithium carbonate,lithium hydroxide,lithium iron phosphate,ternary precursors,and ternary materials,as well as in ceramics,chemical engineering,plastics,mining,food,and other industries.

参数

Classification and Characteristics

Suspended Permanent Magnetic Separator:Suitable for the space above the conveyor belt,it is hung above the conveyor belt through a hanger.It is easy to install and the hanging height can be adjusted as needed.Its ideal installation position is directly above the parabola where the material leaves the conveyor belt,maximizing the separator's capabilities.It can be used in conjunction with various belt conveyors,vibrating feeders,or chutes to remove various ferromagnetic substances from moving materials.

Permanent Magnetic Self-Dumping Separator:Composed of neodymium iron boron permanent magnetic cores,waste iron belts,reduction motors,frames,drums,and other parts,it is used in conjunction with various conveyors to automatically remove ferromagnetic substances from non-magnetic materials.It is especially suitable for situations where materials contain a high proportion of iron impurities.Through the rotation of the belt and the design of the non-magnetic area,continuous and automatic iron removal is achieved,greatly improving production efficiency and reducing daily maintenance workload.

Pipeline Permanent Magnetic Separator:Mainly used for iron removal in pipeline materials.During the flow of materials in the pipeline,magnetic impurities are adsorbed onto the permanent magnets on the pipeline wall.It is commonly used for iron removal of powdery or granular materials in industries such as chemical engineering and food.It has the advantages of easy installation,space-saving,and good iron removal effect.

Flat Permanent Magnetic Separator:With a simple structure,it is usually installed below chutes or vibrating feeders to remove ferromagnetic impurities from non-magnetic materials.It is suitable for situations where the iron removal requirements are not particularly high and the material flow is small.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!