Permanent Magnetic Separators for Mining, Chemical & Food Industries - Ensure Product Purity

Structural Composition

Magnetic System:It is the core component of the permanent magnetic separator,composed of high-performance permanent magnetic materials such as neodymium iron boron,which can generate a strong and stable magnetic field.

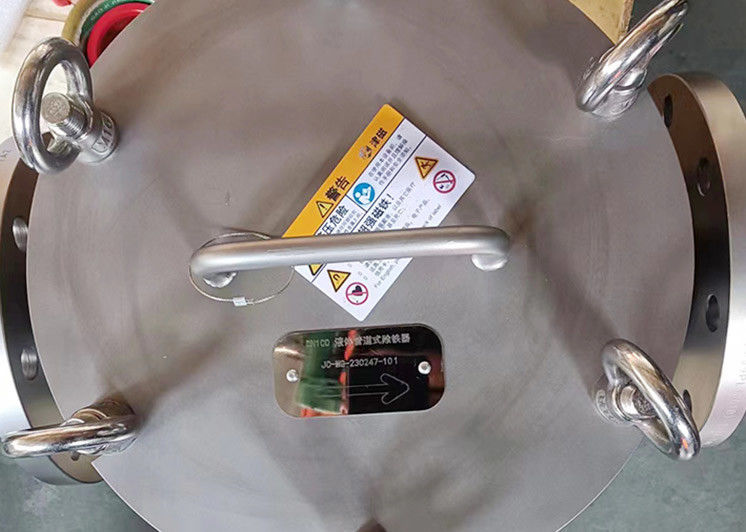

Shell:Generally made of stainless steel or carbon steel,it protects the magnetic system and supports the structure.It also has excellent wear resistance and corrosion resistance.

Drive Device:For some rotating permanent magnetic separators,such as belt-type permanent magnetic separators,the drive device is used to drive components like conveyor belts or magnetic drums to rotate,enabling materials to pass through the magnetic field area evenly.

Features

No Electric Power Needed:The permanent magnetic separator operates relying on the magnetic field of permanent magnets,eliminating the need for external power supply.This saves energy,reduces operating costs,and ensures that the iron removal effect will not be affected by power outages.

High Magnetic Field Strength:By using high-performance permanent magnetic materials,it can generate a powerful magnetic field,effectively adsorbing even tiny magnetic impurities and achieving high iron removal efficiency.

Simple Structure:The equipment has a relatively simple structure,facilitating maintenance.With a long service life,it reduces equipment maintenance costs and downtime.

Strong Adaptability:Different types and specifications of permanent magnetic separators can be selected according to various material characteristics and iron removal requirements,enabling it to adapt to harsh working environments.

Selection Guide

Selection Based on Impurity Removal Rate Requirements and Site Environment:For places with high iron removal requirements,such as coal transportation ports and large thermal power plants,choose permanent magnetic separators with high magnetic field strength and good iron removal effects.In harsh environments like dusty and humid conditions,select equipment with good sealing performance and strong environmental adaptability.

Consideration of Installation Location:When installed at the head of the belt conveyor,the materials are in a loose state when leaving the belt,which is conducive to iron removal.When installed in the middle of the belt conveyor,non-magnetic flat idlers can be used to improve the iron removal effect.Special designs are required for special site environments.

Configuration for Multi-Stage Iron Removal:When multi-stage iron removal is adopted,the iron removal capacity of the subsequent stage should be stronger than that of the previous stage to ensure the iron removal effect.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!